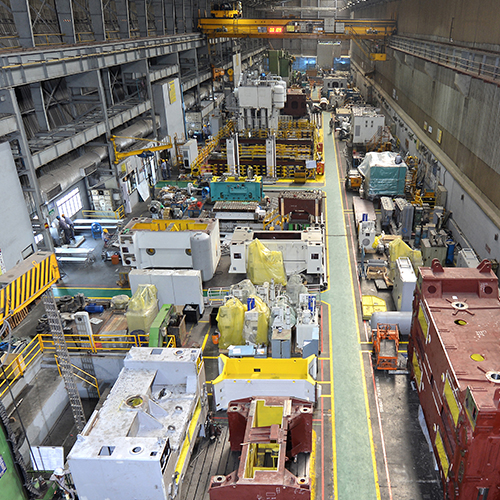

State of the art facilities for boiler component manufacturing

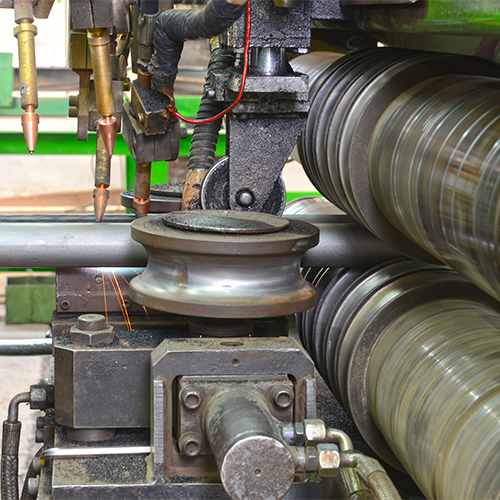

Rolling : Thickness - 300 mm (12 inches)